In the vast domain of industrial maintenance and safety, ensuring the structural integrity of tubular components is critical. The Internal Rotary Inspection System (IRIS) is an advanced ultrasonic method used for inspecting the integrity of tubes in various industrial equipment such as boilers and heat exchangers.

Utilizing a rotating turbine equipped with a transducer, IRIS performs inspections by emitting ultrasound waves through water, which acts as a couplant.

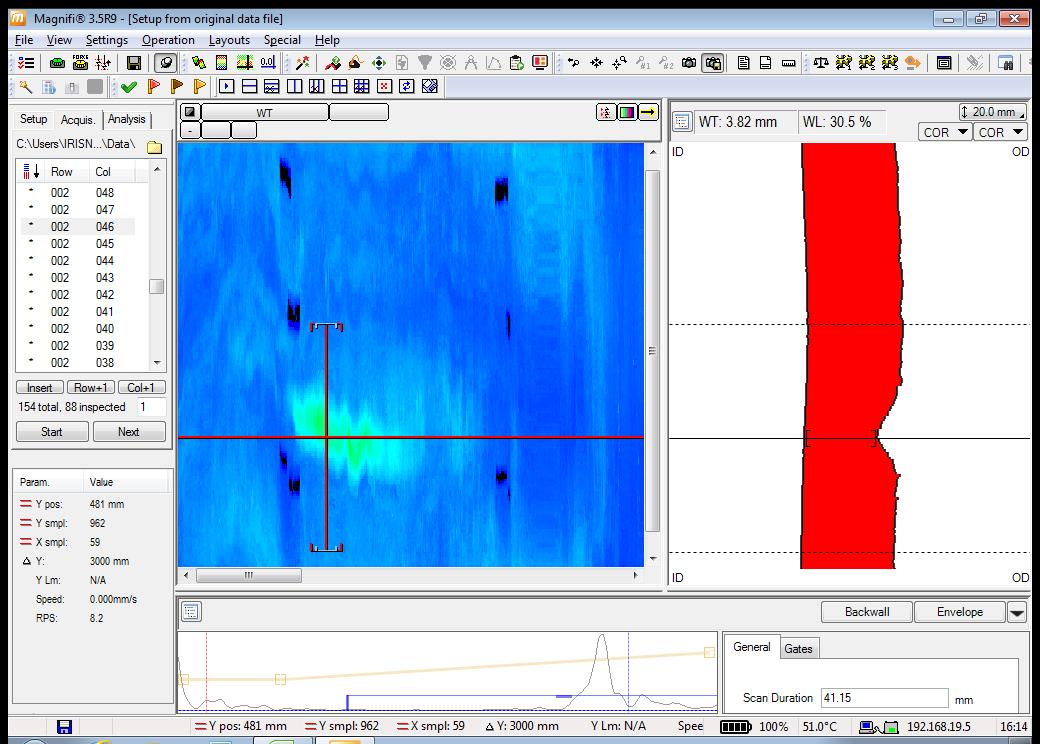

As the probe travels down a tube, it sends pulses parallel to the tube’s axis, which are reflected off the inner and outer diameters of the tube walls. These reflections help determine wall thickness and detect defects by measuring the time differences in the wave’s travel. A key feature of IRIS is its ability to provide a helical scan, ensuring thorough assessments.