In the dynamic world of manufacturing, maintaining product quality, structural integrity, and efficient operations is crucial. Eddy Current Testing (ECT) stands out as a cutting-edge non-destructive testing technique that effectively meets these demands.

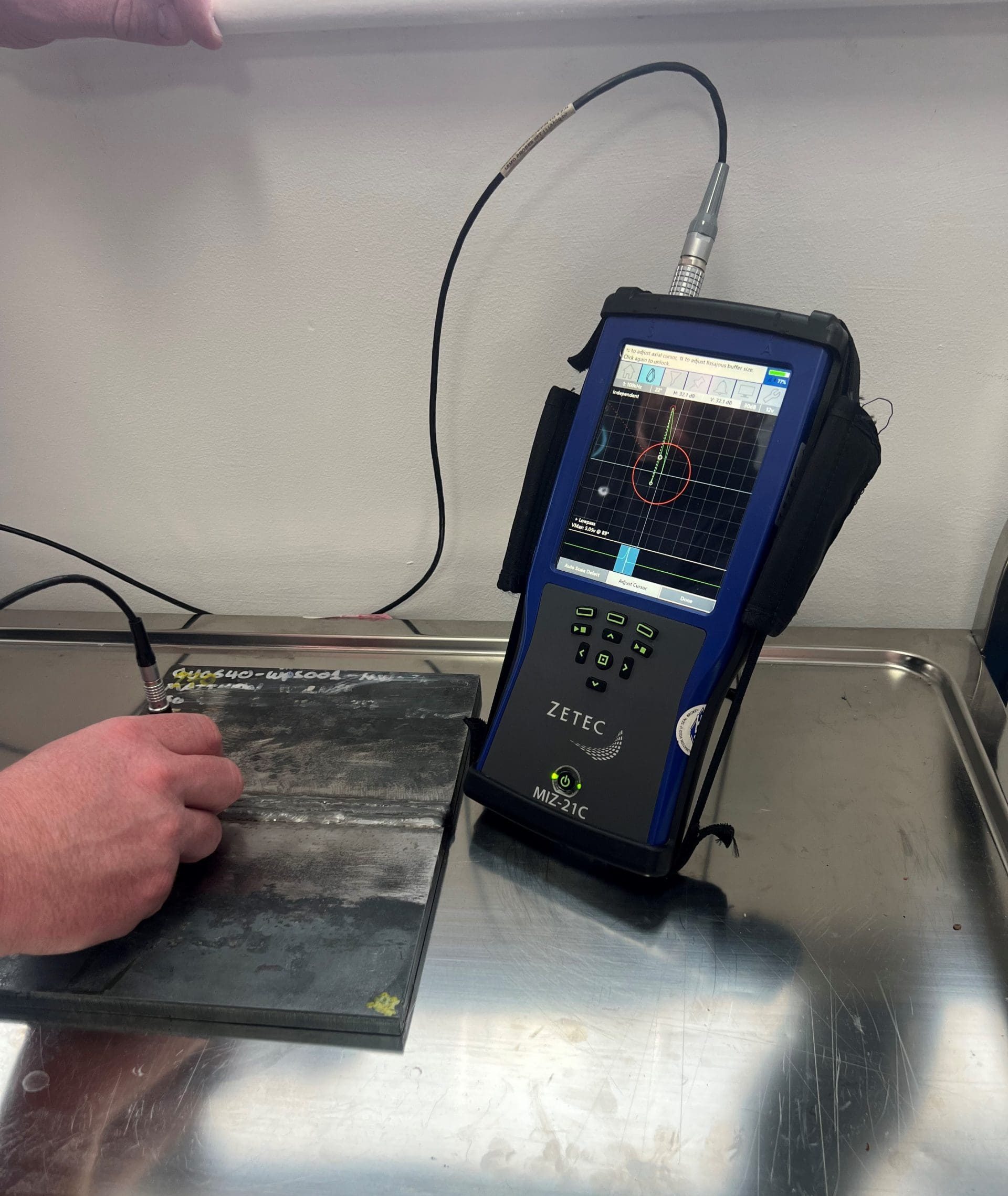

This method utilises electromagnetic induction to detect flaws such as cracks in conductive materials without causing any damage. It operates by passing an alternating current through a coil, generating eddy currents in the material under examination. The response and behaviour of the currents are then analysed to pinpoint defects or variations in the material’s properties, ensuring seamless and effective quality control.

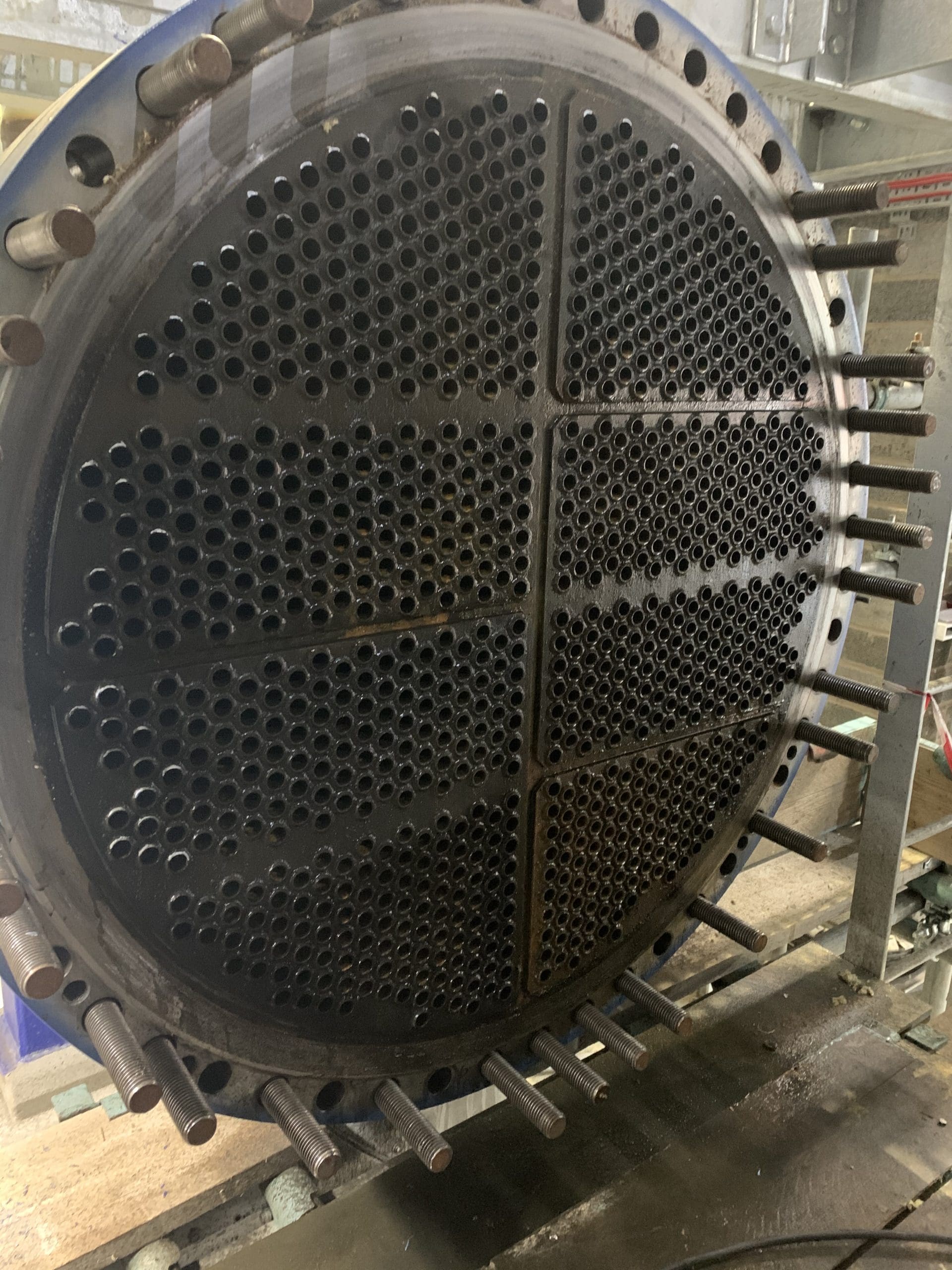

Regular inspection of key assets like heat exchangers, condensers, air coolers and boilers is vital for ensuring safety and operational efficiency across industries, regardless of the material – whether ferromagnetic or non-ferromagnetic.

Eddy Current Testing for Non-Ferrous Materials

ECT is an effective method for assessing the condition of non-ferrous materials like tubes. It identifies and sizes defects including corrosion, pitting, cracks, and erosion through electromagnetic induction. A probe is inserted into the tube’s bore, collecting comprehensive data along its entire length.