In the rapidly evolving world of technology, the need for high-quality, dependable, and secure equipment is ever-increasing.

A crucial factor that bolsters equipment reliability is the stringent quality control process involved in its creation and maintenance. Non-Destructive Testing (NDT) plays a pivotal role in guaranteeing the structural integrity and longevity of products, while simultaneously reducing risks and costs.

In this blog, we will delve into the significance of NDT in both the manufacturing and Asset Integrity management of the equipment lifecycle, emphasizing its advantages and applications.

NDT comprises a set of techniques employed to assess the quality of materials, components, or systems without inflicting damage upon them.

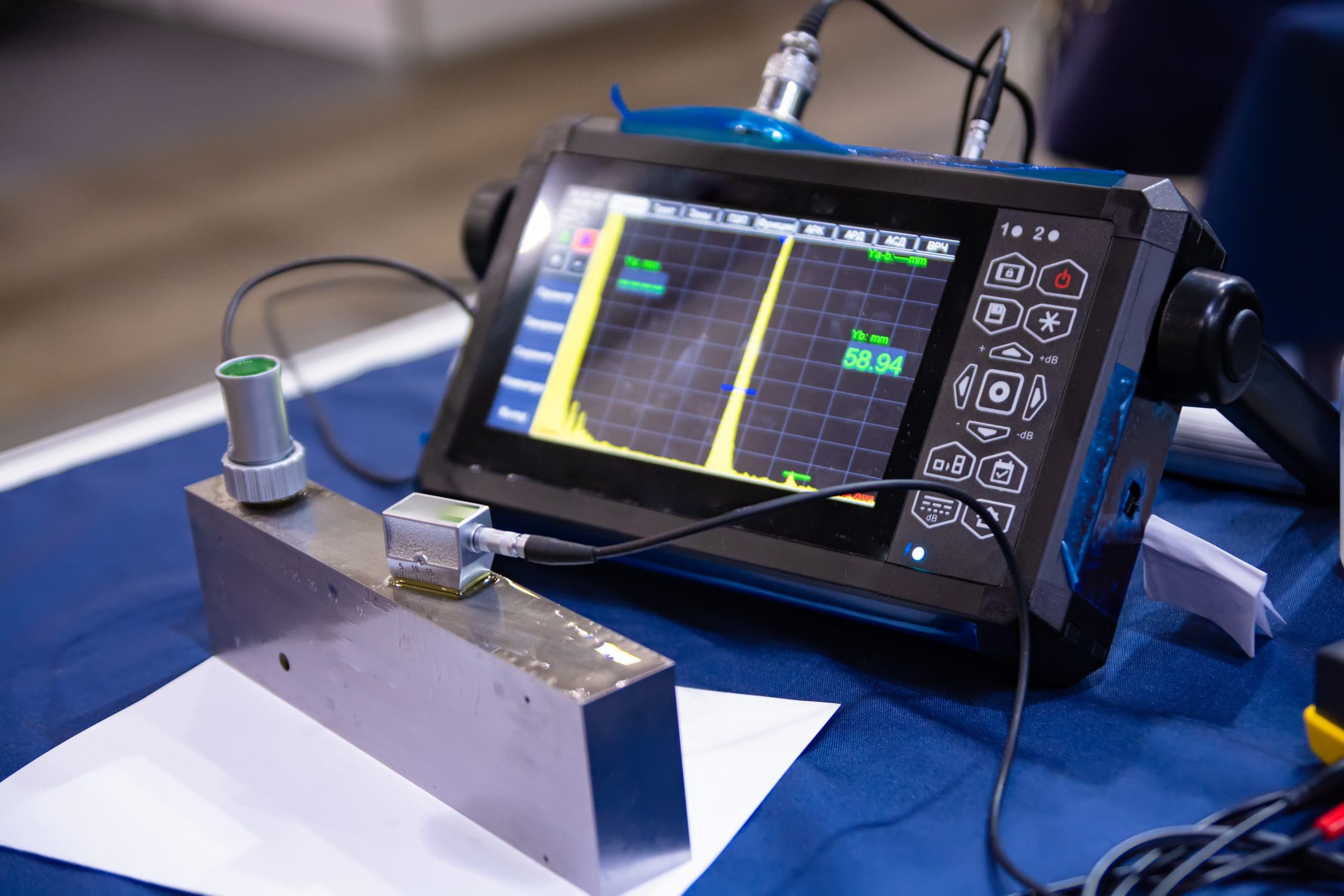

In manufacturing, NDT is utilized to detect defects and inconsistencies in products or materials at various production stages. Widely used NDT methods include ultrasonic testing, radiographic testing, magnetic particle testing, and eddy current testing. The significance of NDT in manufacturing stems from its ability to:

A. Ensure Product Quality and Reliability

NDT aids in pinpointing defects and inconsistencies in materials or components during the early stages of production. This empowers manufacturers to address issues swiftly, guaranteeing that only top-quality and reliable products enter the market.

B. Reduce Production Costs and Waste

By identifying defects early, NDT enables manufacturers to minimize material waste and cut down on rework or repair expenses. This results in more streamlined production processes and cost savings for manufacturers.

C. Meet Industry Standards and Regulations

Numerous industries, such as aerospace, automotive, and energy, adhere to strict quality control standards and regulations. Employing NDT techniques assists manufacturers in complying with these requirements, ensuring the safety and reliability of their products.

NDT also plays an integral role in inspecting and maintaining in-service equipment also known as Asset Integrity Management

Regular NDT inspections contribute to:

A. Ensuring Safety and Preventing Accidents

Equipment failure can result in devastating accidents, inflicting harm on people, property, and the environment. NDT assists in identifying potential problems in equipment, averting accidents, and ensuring the safety of users and the surrounding environment.

B. Prolonging Equipment Lifespan

Detecting and addressing defects and damage in in-service equipment enables timely maintenance and repairs. This helps extend the equipment’s life, maximizing its value and reducing the need for premature replacements.

C. Reducing Downtime and Maintenance Costs

NDT inspections facilitate the identification of problems before they escalate, allowing for scheduled maintenance and repairs. This leads to diminished downtime and maintenance costs, ensuring that equipment remains operational and productive for extended periods.

Non-Destructive Testing is an indispensable aspect of both manufacturing and Asset Integrity management.

By ensuring the quality, reliability, and safety of products and equipment, NDT plays an essential role in meeting industry standards, minimizing costs, and mitigating risks. As industries continue to innovate and evolve, NDT techniques will remain vital in upholding the elevated levels of quality and safety demanded by customers and regulators.

Don’t let your business lag when it comes to quality control and equipment reliability.

Get in touch with NECIT NDT division today at ndt@necitservices.com to explore how our expert team can deliver the most suitable Non-Destructive Testing solutions tailored to your industry and requirements.